Large Bore Cannon

Time to make the first part. Here goes nothing… I’ve used a lathe, but never to make something that needed to be this precise. I’m going to make the back of the cannon first since it's the simplest part. This part is basically just a disk with a threaded hole and an o-ring groove.

Time to make the first part. Here goes nothing… I’ve used a lathe, but never to make something that needed to be this precise. I’m going to make the back of the cannon first since it's the simplest part. This part is basically just a disk with a threaded hole and an o-ring groove.There will radial screw holes around the circumference eventually, but I’m putting that off for now.

I ran into a problem right off the bat. I only have access to a small lathe, and the 3 jaw chuck (which is self centering) won’t fit this disk. There’s a 4-jaw chuck that would fit it, but that one’s not self centering. If I knew what a dial-indicator was at the time I could have used that.. but live and learn.

I was able to just eyeball the center for the first pass. To re-align it after flipping it I pushed the center on the tail-stock into the through-hole. I then gently and progressively tightened the jaws. It seemed to spin smoothly afterwards, so Id say it was a success.

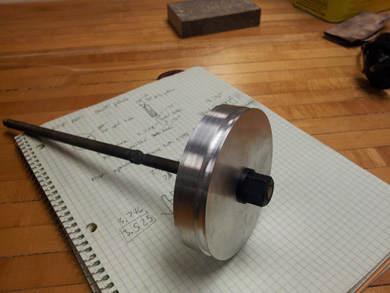

I was able to just eyeball the center for the first pass. To re-align it after flipping it I pushed the center on the tail-stock into the through-hole. I then gently and progressively tightened the jaws. It seemed to spin smoothly afterwards, so Id say it was a success. Here’s the finished part after I turned and faced the other side, and cut the o-ring groove. To cut the groove, I took the advice of some people on the practical-machinist forum and ground an old broken tool down to so it had the same profile as the groove. The tool was wide with a flat nose, so I didn’t think it would cut well, but I used a lot of cutting fluid and it actually cut a perfect groove without too much trouble.

Here’s the finished part after I turned and faced the other side, and cut the o-ring groove. To cut the groove, I took the advice of some people on the practical-machinist forum and ground an old broken tool down to so it had the same profile as the groove. The tool was wide with a flat nose, so I didn’t think it would cut well, but I used a lot of cutting fluid and it actually cut a perfect groove without too much trouble. It came out really nice. No alignment issues at all. I kissed the edges with a file to take the sharpness away.

It came out really nice. No alignment issues at all. I kissed the edges with a file to take the sharpness away.